Commercial Electrician in Minneapolis, MN

An important part of owning commercial property in Minneapolis is ensuring that you have electrical work that meets all code requirements. Whether it’s a new build or a remodel job, the team at 4Front Energy can handle all your commercial electrical needs. After all, we’re a service company, not a sales company.

When you need commercial electrical services in Minneapolis, MN, look no further than the team at 4Front Energy. Call (952) 933-1868 to schedule an appointment.

Office and Store Lighting

Our team is well-versed in adding or repairing various commercial lighting fixtures. We offer lighting replacement and repair services for inside commercial units in St. Paul. These services involve our technicians inspecting your unit, creating a solution plan, and repairing or replacing your existing lights.

Being a business owner, you hold a hand in the well-being of your customers anywhere on your property. This fact creates the need for safe and secure lighting for areas such as backways and parking lots that your customers use. We offer light replacement and repair services for areas outside your building, such as parking lots.

To explore office and store lighting options in Minneapolis, MN, call (952) 933-1868 and request a free estimate from 4Front Energy.

EV Chargers for Businesses

With the changing market, you must keep up with customer needs. This is why an EV charging station is important to your business. Minnesota is starting to see its electric car market grow, bringing it up to par in no time. Getting ahead of the curve is better than playing catch-up.

The energy costs of a charging station can be offset by the goodwill built with your customers who own electric cars. Additionally, it’s a great look for your business. It will promote energy responsibility within your company and with your customers.

Commercial Electrical Repairs in St. Paul

The last thing you want for your business is to have shoddy electrical work. Low-quality electrical work can put you and your customers at risk, so we offer commercial electrical repair services in St. Paul.

Our electrical services include the following:

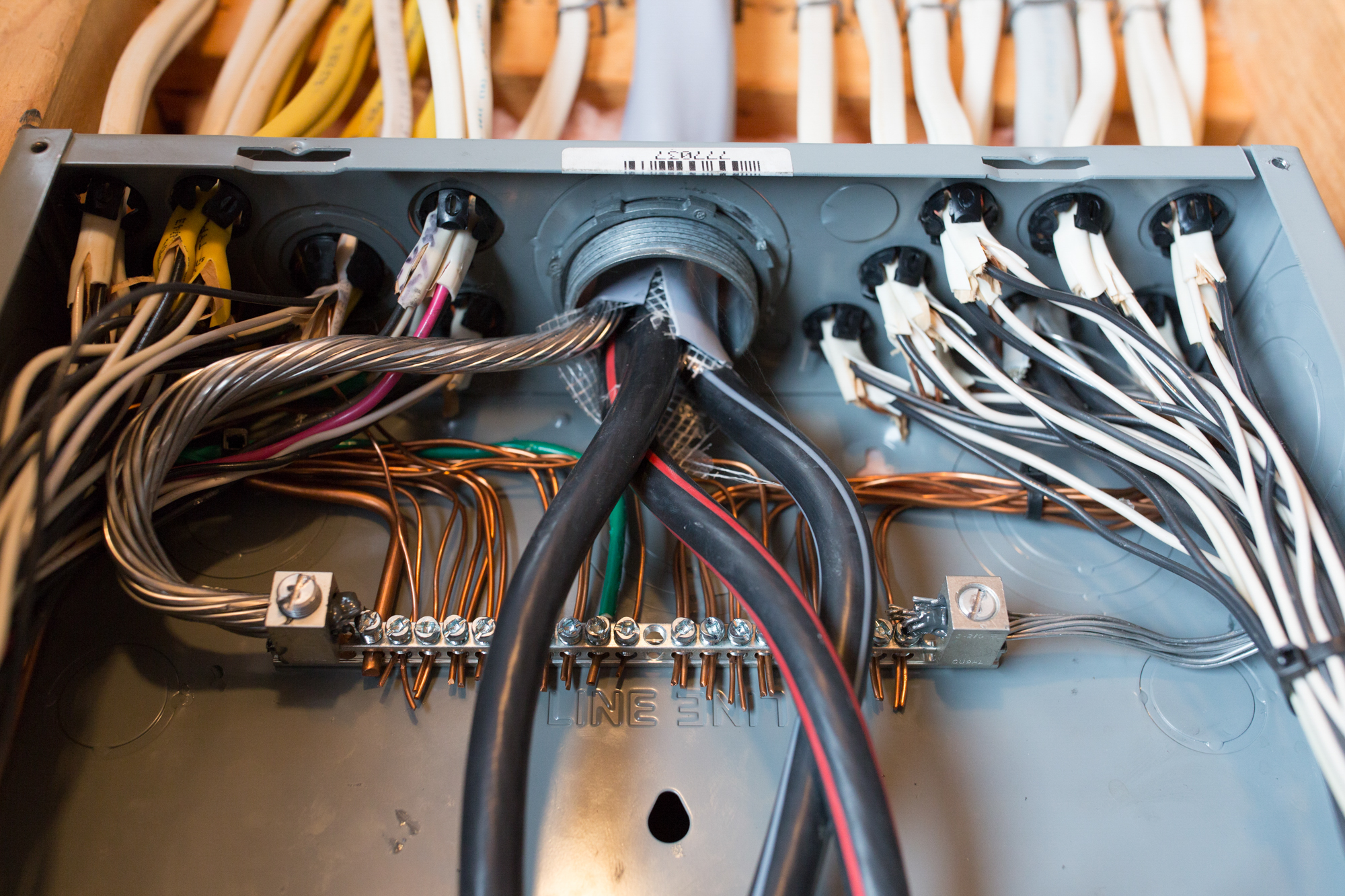

- Panels: Only trained technicians can install the proper panels to match your energy needs.

- Wiring: Whether replacing old wires or installing a new set, our trained technicians are ready to handle any wiring needs.

- Generators: A great way to provide stability to your business is by having an emergency generator, something the 4Front team can install.

- Ceiling fans: You want your clients to be comfortable in your building; ceiling fans are a great way to provide that comfort.

Call (952) 933-1868 and request an appointment for commercial electrical repairs in Minneapolis with 4Front Energy.

Why Choose Us?

You can trust the 4Front Energy team at every step of the way. For nearly 30 years, our four branches served the Minneapolis region before coming together as one beacon of hope for electrical repairs. Don’t just take our word, though. Learn what previous customers have had to say about their time with 4Front Energy.

For commercial electrical services in Minneapolis, call (952) 933-1868 and request a free estimate from the 4Front Energy team today.